Spiers New Technologies (SNT) is just over a year old, but its founder has been focused on developing the market and technology for secondary-use batteries as long as anyone in the business. Dirk Spiers is one of the more passionate figures in the EV industry. Like many entrepreneurs, he seems to have a clear view of where technology is headed and a burning desire to make it happen quickly.

Since the launch of the Nissan LEAF and Chevy Volt in 2010, we’ve heard a lot of talk about the possible applications for reusing battery packs once the useful life of the car has come to an end. Second-life EV batteries in commercial applications offer the potential for highly-capable energy storage products at substantially lower costs. After about 10 years on the road, a lithium-ion battery pack still has as much as 70-80 percent of its original capacity. This offers a great deal of value for many non-automotive applications, including storage for intermittent renewable energy sources like solar and wind, back-up power and load-shifting for commercial buildings, and large-scale demand management for the grid.

SNT is one of just a small handful of companies we’ve seen actively developing technology for repurposing batteries. One of the company’s core goals is to streamline the process of moving the batteries from the car to their next application, which will be critical if systems are to deliver on the promise of low costs. SNT’s customers already include several of the major plug-in vehicle manufacturers.

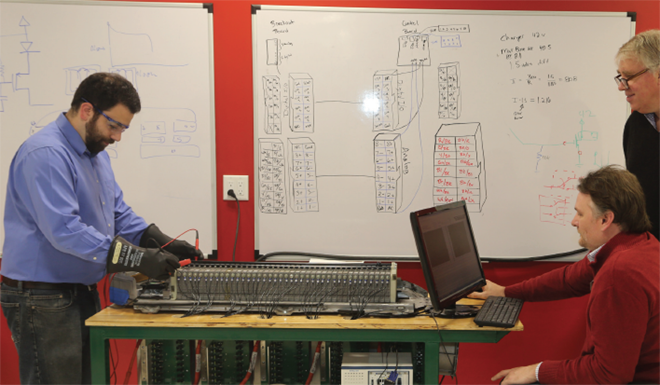

To get a better idea of SNT’s capabilities, Charged recently talked to President Dirk Spiers, Head of Engineering Bryan Schultz and Algorithms Research Engineer John Junger.

Charged: Can you describe where SNT fits into the process of moving battery packs from the vehicles to their next applications? What exactly is your relationship with the automakers?Â

Dirk Spiers: We call it lifecycle management for advanced battery systems, and we offer the “4 R†range of services within that – repair, remanufacturing, refurbishing and repurposing.

It starts with the recovery of the core, which is the battery pack that comes out of a vehicle. We help the OEMs to bring all used cores to a central location and check them for any safety issues. Today, most of those packs are coming from dealers who have done warranty replacements and from things like test projects that have concluded. We collect all of the batteries’ data in the background, and have built some pretty advanced database management software.

If the pack came out of a vehicle because of a warranty issue, we start with a root cause analysis to determine what the issue is and then repair it.

The next step is to choose between remanufacturing, refurbishing, or repurposing. Remanufacturing is to restore a pack to its original specification, refurbishing is to restore it to a later specification, and repurposing is to determine the second-life opportunities for a pack as it is.

In each case, classification of the state of the cells, modules and pack is very important. This is the grading step, and it’s critical because it gives the foundation for determining what is the best future use of the batteries. So we’ve spent a lot of time and resources developing a very robust and advanced grading engine for the packs. We try to do it as quickly as possible, because the more efficient we are, the better it is, as volumes will be ramping up over the next few years. The grading tells us which packs are good enough to go back into a vehicle and which are better suited for the second-use market, which is almost exclusively some form of stationary energy storage.

And, finally, when a pack has significant wear and no useful life left (or the OEM tells us they don’t want it repurposed for whatever reason) we tear it down to its smallest possible parts, and recycle everything.

We also handle all the outbound logistics to get the packs back to either the dealer or OEM for another vehicle, or to the next customer.

So we have this complete spectrum of services like a buffet. Some customers want us to handle all aspects for them, and others are just looking for one or two items.

Charged: What exactly are you testing for during the classification and grading process?Â

Bryan Schultz: We test for a range of things, including capacity, internal resistance and response. Those parameters can change a lot depending on how the battery was originally used. We look at what applications a specific set of battery packs are going to next, and then create a custom set of weights to figure out which of those parameters are important for reuse. All of this is dependent on the specific chemistry of the cells in the pack, and we work with a variety of chemistries for both nickel-metal hydride and lithium-ion packs.

We see packs that are still really good except for one problem that caused a system error. It’s not usually an independent cell that fails, because they’re manufactured to such a high standard. It’s usually a thermistor failure or a bolt on the bus bar that came loose, which are good candidates to be fixed and sent back to the original application.

On the other hand, we also see a lot of packs that have cell degradation across the board. These are usually still fairly strong batteries but not quite good enough to justify going back into a vehicle. This is usually a drop in capacity due to normal aging. Imagine a battery that’s been on the road for 80,000 miles, and something unrelated to the battery cells fails, say a thermistor. Because it’s been on the road so long, all of those cells have aged a certain amount. If a dealer is going through the effort of replacing a pack in a car, they’re typically going to use a pack that’s closer to brand-new. So the pack in this example would be headed to something like a grid-tied system for shifting load away from peak demand or doing frequency regulation.

Not all stationary applications are equal. Smoothing out the output from a large solar array is a pretty demanding job for a battery because of how quickly the output can change. So if you have a battery that is more degraded, there are easy applications for the second use, for example in a building that does a little bit of energy shifting and occasionally acts as a backup power source during outages.

John Junger: We’re also moving into the aftermarket parts market. We can remanufacture packs for the original application and basically supply parts that you would go to the parts store to buy. Some NiMH hybrid systems are now becoming more commoditized, so you can work on them yourself if you’re comfortable around relatively higher voltage, and they are selling parts in the aftermarket. That’s a big avenue for second life because you can supply good batteries for a significant reduction in cost. So they would be labeled as remanufactured batteries and warrantied either through us or the final distributor.

Dirk Spiers: What is very important with advanced battery packs is that everything is in harmony. In a way it’s better to have 10 mediocre modules that are always in harmony than to have an assembly of 10 in which 8 are terrific and 2 are not great. That’s another reason why grading is so important, because it allows you to put something together again where everything is in balance and in harmony and therefore will have a much longer life.

A lot of credit goes to our team that developed these very advanced mathematical models that allow us to analyze what we see and translate it into a process which is really accurate and quick. I think that’s what really sets us apart.

Charged: You mentioned that you’re constantly improving the grading process. In what ways?

John Junger: The main thrust is to continually reduce the amount of time we spend on a channel and maximize throughput. To grade batteries requires you to take measurements while cycling – charging and discharging. That’s usually done at low currents to increase the accuracy of the measurements. We’ve been able to develop ways to do it at higher currents and save a lot of time by deriving a linear relationship between charging at higher and lower currents for different chemistries. This allows us to arrive at the same values quicker. So Instead of tying up a testing channel for 12 to 24 hours, we can use it for only one to two hours and get the same results within a statistical significance.

Bryan Schultz: Basically we’re trying to take the gold standard test that the OEM provides for their specific cell chemistry, then look at either lowering the SOC window or speeding up the cycling. We’re trying to find the boundary where it begins to break down on the curve and then determine where we can speed up the test as much as possible without losing accuracy. This process is customer-specific and model-specific. So if a customer came in with a different chemistry or battery packs from a different vehicle model, we’d have to start the optimization process over.

When we get the initial batch of batteries from the same source, we’ll test them and develop these optimizations. To begin building up the algorithm, we start on cell level, then module and pack level. Then we’ll periodically verify that the grading optimizations are relevant for the ongoing population of packs that we’re receiving. Things can change over time, of course, so we continually verify that our original process is adequate statistically with the current batch of cells that we’re testing.

Over time we’ve built different methods for different chemistries of both Li-ion and NiMH.

Charged: How do your OEM customers feel about you building upon their testing standards?

Dirk Spiers: That can take some convincing. We recently had some very long discussions with one OEM about the accuracy of our process before they came around.

OEMs know their battery packs really, really well. They’re really smart engineers and they know their stuff. But I like to think of them as being like early mothers. They give birth to their battery pack and they know it better than anyone else. But at some point the batteries go out into the real world and things start to change. So we’re a bit like a daycare center that needs to prove that we’ll take care of their battery packs. Eventually we need to test them to be able to compare them to others, and because our testing methods may be different from the OEM’s, we need to explain why they are just as effective.

We went back and forth with one OEM that wanted us to continue to use their methodology – which I completely understand. However, we were certain that our process was better, so we didn’t relent. After many discussions, they eventually came around. Actually, they told us that they’re now using our method too, and have it in their documents as the “SNT method,†which they are now standardizing for these measurements.

That was very rewarding to be able to talk to top OEM engineers at their level and convince them of the efficacy of our work. To hear them say that, when it comes to this we are ahead of them, is very encouraging to a team of our size.

John Junger: The statistical analysis really carried the argument. I put together a bunch of data to show that what we were finding was an equivalent result to what they had shown. Basically, the issue was that they are trying to sell the residual capacity in the batteries and wanted us to use the slower testing method to be certain it’s measured accurately. We’re also concerned with accuracy, but at the same time we want to process the pack quickly. So only when we can show the tests are equivalent will the OEMs sign off on it.

We also get a lot of insight from the different OEMs, and we always try to make improvements based on their input.

Charged: It seems like the secondary-use market, and SNT in particular, is poised for a lot of growth as the first-gen EVs begin to reach their end of life. Do you think that’s correct?

Dirk Spiers: Yes. I think it’s safe to say we already do more second-life management than anyone else in a commercial setting. We now have over 70,000 square feet dedicated to all of our advanced battery pack services – we’re also building and testing stationary energy storage systems. The one-stop-shop concept really resonates with the OEMs because it saves costs and it makes it much easier to manage and coordinate for them.

We have groups from all over the world visiting us on a regular basis to discuss what we do and how we do it. More than one of them has told us that we’re the leaders by a mile, based on others they’ve visited.

Source: ChargedEVs