The Intertubes have been buzzing with news that the humble loofah sponge can improve the performance of lithium-sulfur batteries, by contributing a layer of carbon to the cathodes. The new layer provides for stability and durability, which is good news for EV fans looking for the cost of electric mobility tech to continue dropping — and for the range of EV vehicles to go up.

Renewable Carbon For Your EV Battery

The new energy storage research comes from a team based at the Centre for Clean Environment and Energy at Australia’s Griffith University. You can find it at the journalApplied Materials & Interfaces under the title, “Multifunctional Nitrogen-Doped Loofah Sponge Carbon Blocking Layer for High Performance Rechargeable Lithium Batteries.“

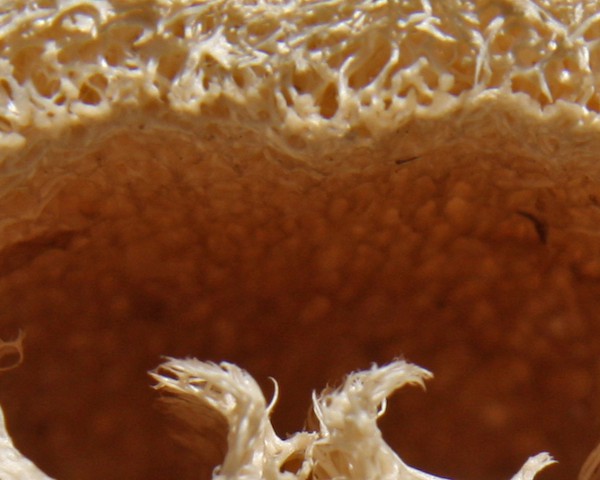

In the study, the authors describe how they derived carbon from a loofah sponge and synthesized it into a “low-cost, hierarchically porous, and nitrogen-doped†form of carbon by using a “simple†process involving exposure to high heat.

They applied the specialized carbon, dubbed N-LSC, to the cathodes in lithium-sulfur (Li-S) batteries along with two other battery types, lithium-selenium and lithium-iodine. According to the abstract, the result was “outstanding electrochemical performance stability in all cases:â€

…high reversible capacities of 623.6 mA h g-1 at 1675 mA g-1 after 500 cycles, 350 mA h g-1 at 1356 mA g-1 after 1000 cycles, and 150 mA h g-1 at 10550 mA g-1 after 5000 cycles, respectively.

To be clear, there is still a long way to go between the new research and some toasted bits of loofah under the hood of your new EV, but the team has high hopes for N-LSC:

…loofah sponge carbon could play a vital role in modern rechargeable battery industries as a universal, cost-effective, environmentally friendly, and high-performance blocking layer.

Li-S Energy Storage For Your Next EV

Did you catch that thing about Li-S? So did we. With all of its advantages, some day Li-S could give conventional lithium-ion technology a shove out the door.

Li-S is emerging as the next generation of durable, high capacity, light weight, energy storage tech for EV mobility. It is already beginning to poke its way into the commercial mobility market with the US company Solid Power among those first out of the box.

On The Road To An Edible EV

Sodium-ion technology is another emerging energy storage field in which vegetable matter could come into play, and with the vegetable angle in mind let’s check in on The Ford Motor Company.

The raw numbers are still pretty small, but Ford’s use of vegetation in its vehicles has been steadily expanding:

The average Ford vehicle uses between 20 and 40 pounds of renewable materials, depending on the vehicle size class. Almost 300 parts used across Ford’s vehicles are derived from sources such as soybeans, cotton, wood, flax, jute and natural rubber.

No word on loofah yet, but Ford has been looking into the potential for making a rubber substitute from dandelions.

The company’s carbon fiber research could also lead to a rapid expansion of its use of bio-based materials. Last summer, Ford nailed down $6 million in Energy Department funding for advanced carbon fiber research, and the Energy Department has been quite interested in bio-derived materials for the automotive market.

Just last year, Oak Ridge National Laboratory issued an update on its research, indicating good near-term potential for non-structural uses of bio-based carbon fiber.

Structural use is a whole ‘nother topic but is also within sight. Sweden, for example, has established a carbon fiber roadmap that anticipates a high performance wood-derived product by 2025.

Source: Cleantechnica