Lithium-sulfur batteries are of great interest, as they could offer specific energy densities far greater than those of current lithium-ion chemistries. However, current designs are plagued by low efficiency and capacity degradation.

A team of researchers from the University of Cambridge and the Beijing Institute of Technology has devised a three-dimensional sandwich-type graphene sheet-sulfur/carbon composite to address these performance-related issues.

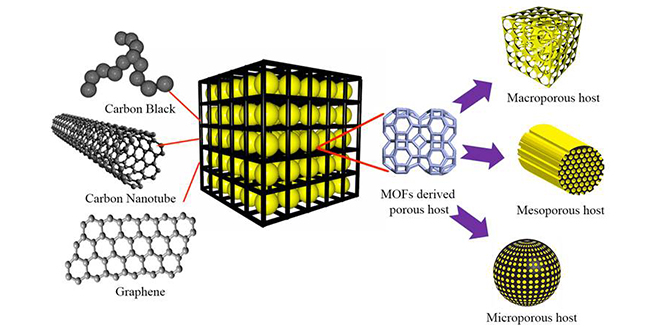

In the journal APL Materials, Dr. Vasant Kumar and Professor Renjie Chen describe how they used a metal organic framework as a template to produce a conductive porous carbon cage in which sulfur acts as the host and each sulfur/carbon nanoparticle acts as an energy storage unit where electrochemical reactions occur.

A thin sheet of graphene, wrapped around the sulfur/carbon composite, has excellent electrical conductivity and mechanical flexibility. This facilitates rapid electron transport and accommodates the changes in volume of the sulfur electrode. Compared with an unwrapped sample, Li-S batteries with the composite cathode showed enhanced capacity, improved electrochemical stability up to 120 cycles, and relatively high Coulombic efficiency.

“Our carbon scaffold acts as a physical barrier to confine the active materials within its porous structure,†explained Kai Xi, a research scientist at Cambridge. “This leads to improved cycling stability and high efficiency.†This work provides a “basic, but flexible, approach to both enhance the use of sulfur and improve the cycle stability of batteries. Modification of the unit or its framework by doping or polymer coating could take the performance to a whole new level.â€

Source: ChargedEVs