Zinc-air batteries are widely used in devices like hearing aids for their good performance-to-price ratio. The tricky part is of course to make them rechargeable. This is one of two technologies that ZAF Energy Systems has been working on for the last couple of years. [Note that CleanTechnica published an article about this technology back in 2013.]

Recently, the video of a pre-sales meeting from June 2015 at Microsoft Research was released. First and foremost, ZAF’s goal was to find a premium partner for mobile devices. Eventually, Microsoft’s product team got excited, acknowledging that ZAF is ahead of competing zinc air batteries. Below is the video, followed by a short summary.

Here is a rundown of ZAF’s claims:

- Projected 500 cycles at 75% roundtrip efficiency.

- Twice the volumetric and gravimetric energy density of lithium-ion batteries.

- Established manufacturing equipment can be used.

- No formation is necessary (lithium-ion cells tie up capital for weeks before being deployable).

- The pouches are resilient to contaminations (heat sealed only).

- Easy to recycle and safe (solid electrolyte).

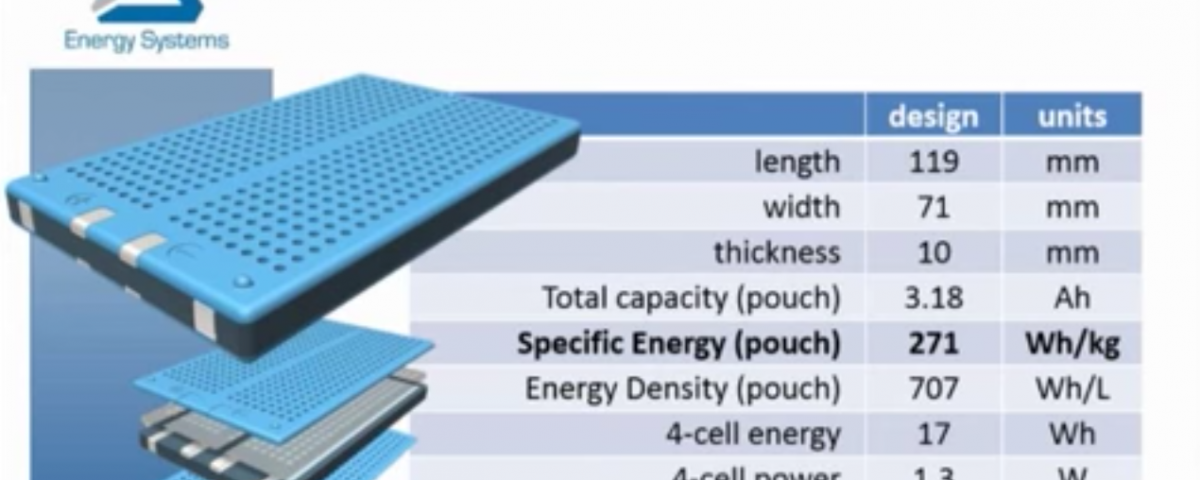

A prototype consisting of four pouches was brought to the meeting. Its lifetime was 40 fully discharged cycles, which is a fourfold increase within the prior few months. Naturally, taming the growth of pesky zinc dendrites plays a major role in that process. Despite the lifetime being still 12x behind the projected goal, ZAF’s CEO was confident to have royalties rolling in by the end of 2016, be it with or without consumer electronics down the road.

14 patents spread across the internals of the battery bolster ZAF’s claims. Many of them target what often falls short in battery R&D: cheap manufacturability. All together, manufacturing costs are projected to be 1/4th to 1/8th that of lithium-ion batteries. Other key aspects include the membrane in development with the University of Tennessee that prevents the breathing battery running out of water in dry environments, supposedly self-balancing cells, and high flexibility to begin with.

The benign nature of zinc-air chemistry in terms of environmental and fire safety comes at a price too. Among other metal-air batteries, zinc has one of the lowest energy densities. More accurately, zinc-air’s theoretical limit is about 1/10th that of lithium-air with 11,000Wh/kg (a technology that was abandoned in 2014 by two influential proponents but recently revivedin some variants). Also, draining the battery in less than 2 hours would require forced air supply. If all bears out, though, ZAF’s rechargeable zinc air batteries are within the ballpark of cost and performance to make electric vehicles competitive — a thought that both Microsoft and ZAF engineers entertained.

Apparently, Microsoft is on the lookout for better batteries. One of HoloLens’ strengths is augmenting reality without a tether, and it is probably not the last category of mobile computing to be unlocked by portable power. Ironically, though, quite the opposite happened recently: the Surface Pro 3 suffers from a bad run of ordinary lithium-ion batteries from one supplier. I’m not aware of what progress has been made until today with commercializing zinc-air batteries. Nevertheless, I think it’s worth it to applaud Microsoft for making such details available because one thing is for sure: bringing comprehensive data along with (breakthrough) headlines is a good idea, at least in terms of educational progress.

Source: Cleantechnica