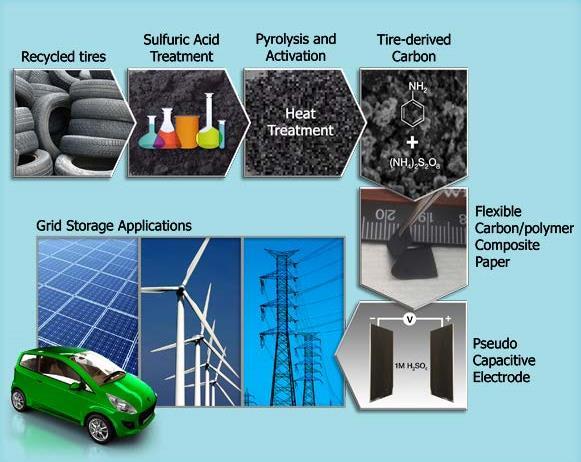

Some of the 300 million tires discarded each year in the US could be recycled and used in electrodes for supercapacitors, using a new technology developed at Oak Ridge National Laboratory and Drexel University.

The process is described in a paper published in ChemSusChem, titled “Waste Tire Derived Carbon-Polymer Composite Paper as Pseudocapacitive Electrode with Long Cycle Life.â€

The ORNL and Drexel researchers produced flexible polymer carbon composite films, using waste tires as a precursor. The narrow pore-size distribution and high surface area led to good charge storage capacity, especially when used as a 3D nanoscaffold to polymerize polyaniline (PANI). The resulting composite paper was highly flexible and conductive, and exhibited a capacitance of 480 F g−1 at 1 mV s−1 with capacitance retention of up to 98% after 10,000 charge/discharge cycles.

To produce the carbon composite paper, the researchers soaked crumbs of tire rubber in sulfuric acid, then washed the rubber and baked it at 1,100 degrees Celsius under a flowing nitrogen gas atmosphere (what fun!). After several additional steps, they had a material they could mix with polyaniline, an electrically conductive polymer.

Manufacturers expect to produce some 1.5 billion tires per year by 2035.

“Those tires will eventually need to be discarded, and our supercapacitor applications can consume several tons of this waste,†said team leader Parans Paranthaman. “Combined with the technology we’ve licensed to two companies to convert scrap tires into carbon powders for batteries, we estimate consuming about 50 tons per day.â€

That’s a fraction of the 8,000 tons that need to be recycled every day, but co-author Yury Gogotsi of Drexel noted that other recycling companies could contribute to that goal.

“Each tire can produce carbon with a yield of about 50 percent with the ORNL process,†Gogotsi said. “If we were to recycle all of the scrap tires, that would translate into 1.5 million tons of carbon, which is half of the annual global production of graphite.â€

“We anticipate that the same strategy can be applied to deposit other pseudocapacitive materials with low-cost tire-derived activated carbon to achieve even higher electrochemical performance and longer cycle life, a key challenge for electrochemically active polymers,†Gogotsi said.

Source: ChargedEVs