Chinese Li-ion battery manufacturer Lishen has ordered four electrode slurry production lines from the Swiss firm Bühler, a contract worth almost $10.5 million.

Over the next few years, Lishen plans to open three new battery factories in China, with a combined annual capacity of 40 GWh, equivalent to about 700,000 average car batteries.

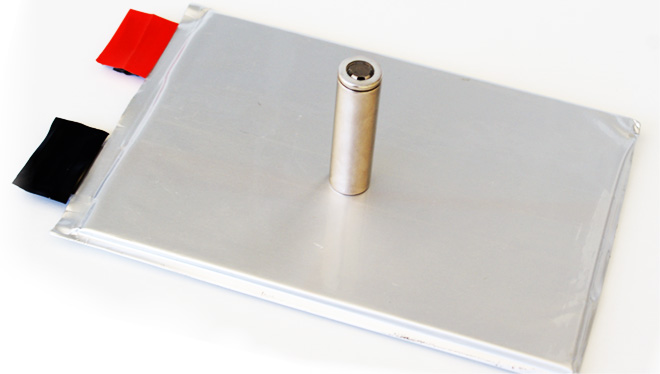

The processing of electrode materials directly affects the efficiency, performance, and capacity of the batteries. According to Bühler, current processing methods are unsuitable for handling the larger volumes that will be required as battery demand grows.

That’s why Lishen and Bühler have been collaborating for several years to develop a more efficient production process, which allows continuous production using a twin-screw extruder. Until now, slurries were mixed batch by batch in large agitator vessels.

The new Bühler process delivers more consistent quality, requires 60% less space, and reduces energy demand by 60%.

“These efficiency increases in the production of the key components are crucial for propagating electric mobility on a large scale,†says Cornel Mendler, Head of the Bühler Business Area Grinding & Dispersion.

Source: ChargedEVs