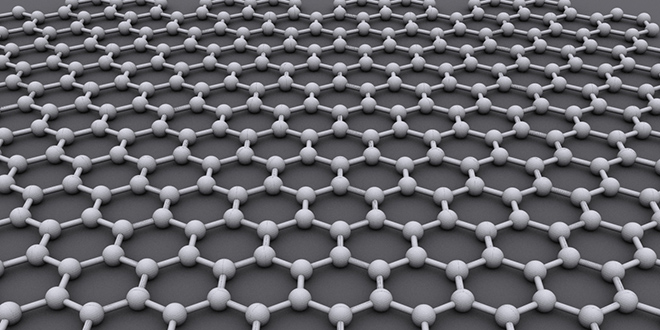

Graphene, a two-dimensional hexagonal lattice of carbon atoms, has great potential in a number of EV-related applications, including anodes, lithium-sulfur batteries and ultracapacitors. With current technology, however, it’s impractical to use on a large scale, and researchers have been limited to using small flakes of the material.

Now a team of researchers at the DOE’s Oak Ridge National Laboratory (ORNL) have fabricated polymer composites containing 2-inch square sheets of graphene, using chemical vapor deposition. The resulting composite structures have the potential to outperform current materials in both mechanical properties and electrical conductivity.

The team’s findings, reported in the journal ACS Applied Materials & Interfaces, could enable large-scale fabrication of graphene composites. “Before our work, superb mechanical properties of graphene were shown at a micro scale,†said ORNL team leader Ivan Vlassiouk. “We have extended this to a larger scale, which considerably extends the potential applications and market for graphene.â€

Most approaches for polymer nanocomposition construction use tiny flakes of graphene that are difficult to disperse in the polymer. Using larger sheets of graphene enabled Vlassiouk’s team to eliminate the flake dispersion and agglomeration problems, allowing the material to better conduct electricity with less actual graphene in the polymer.

“We were able to use chemical vapor deposition to make a nanocomposite laminate that is electrically conductive with graphene loading that is 50 times less compared to current state-of-the-art samples,†said Vlassiouk.

Source: ChargedEVs