An international team of researchers has demonstrated a new way to improve the performance of lithium-rich cathode materials by creating oxygen vacancies at the material’s surface.

In “Gas-solid interfacial modification of oxygen activity in layered oxide cathodes for lithium-ion batteries,†published in Nature Communications, Minghao Zhang and colleagues explain the importance of oxygen atoms in battery materials. According to the team, their process improved the energy density of the cathode material by up to 40 percent.

“We’ve uncovered a new mechanism at play in this class of lithium-rich cathode materials. With this study, we want to open a new pathway to explore more battery materials in which we can control oxygen activity,†said Shirley Meng, one of the principal investigators.

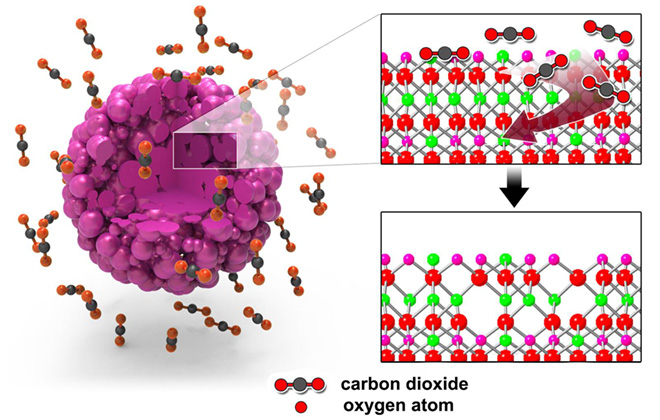

Meng’s group, in collaboration with researchers from the Chinese Academy of Sciences, developed a way to introduce oxygen vacancies in a promising class of cathode materials called lithium-rich layered oxides. Treating the lithium-rich cathode particles with a carbon dioxide-based gas mixture created oxygen vacancies throughout the surface of the particles.

“This is a mild treatment that allows us to make controlled changes in the material exactly where we want – near the interface,†said co-author Minghao Zhang.

The oxygen vacancies allow lithium ions to move more easily throughout the cathode, leading to high discharge capacity and faster discharge rates. They also increase the material’s stability by inhibiting the formation of highly reactive oxygen radicals at the cathode material’s surface.

“We can controllably utilize oxygen activity to improve the performance of the material and better control how it works inside the battery,†Zhang said.

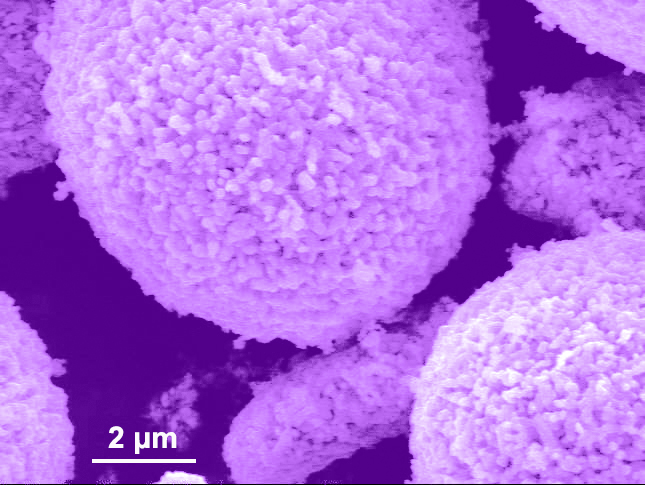

SEM image of lithium-rich cathode particles treated with a carbon dioxide-based gas mixture to introduce oxygen vacancies on the surface.

Source: ChargedEVs