Researchers at the DOE’s Oak Ridge National Laboratory have demonstrated a production method that they estimate will reduce the cost of carbon fiber by as much as 50% and the energy used in its production by more than 60%. After analysis and prototyping by industrial partners, ORNL is making the new process available for licensing.

A detailed analysis of the new process examined the manufacturing costs of nine process steps, from precursor and pretreatment to finishing with surface treatment, sizing, winding, inspection and shipping. Details of the cost analysis, which predicts cost reduction of up to 50%, will be shared with prospective licensees.

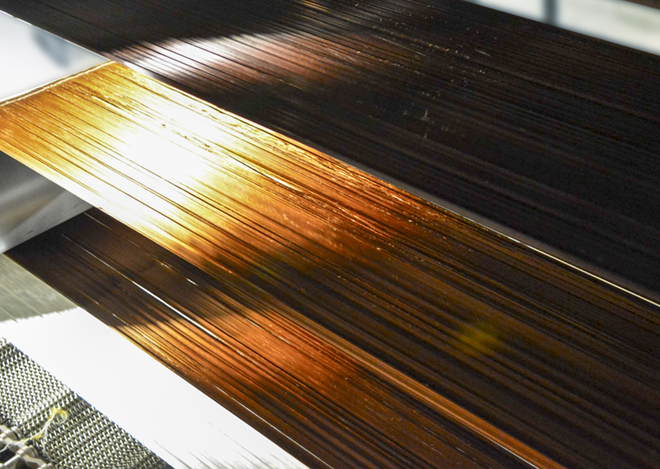

Carbon fiber is currently produced by converting a precursor fiber to pure carbon fiber through a series of heating and stretching steps. The high cost of the precursor material, polyacrylonitrile (PAN), contributes to the high cost of the end product.

Acrylic fiber of similar chemistry, however, is produced on a commodity basis for clothing and carpets – a high-volume product that costs roughly half as much as the specialty PAN used in the carbon fiber industry. ORNL researchers believed textile-grade PAN was a pathway to lower-cost carbon fiber, but lab experiments couldn’t fully explore its potential at production scale.

To provide that capability, the DOE funded research at ORNL’s Carbon Fiber Technology Facility, a highly instrumented, semi-production-scale carbon fiber conversion plant.

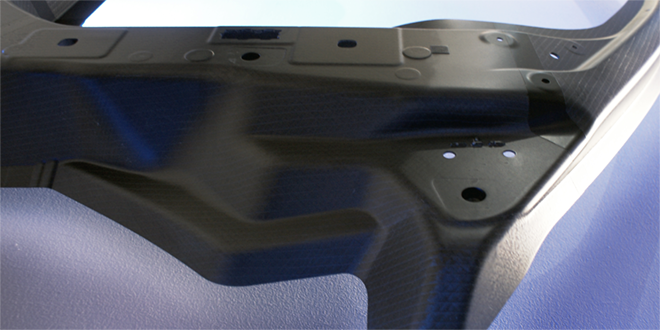

Extensive tests have been performed on carbon fiber from the new process, and several auto manufacturers and their suppliers received quantities suitable for prototyping, with encouraging results.

Companies, including licensees of the new method, will be able to use the Carbon Fiber Technology Facility to refine and validate carbon fiber manufacturing processes.

“Our R&D into process improvements and the extensive validation work at the Carbon Fiber Technology Facility provide manufacturers and end-use industries the confidence needed to invest in large-scale manufacturing, knowing there will be a market for this material,†said Gary Jacobs, ORNL’s Interim Associate Lab Director for Energy and Environmental Sciences

ORNL will be accepting license applications through May 15.

Source: ChargedEVs