A new prototype “intelligent battery cell†has been developed by researchers at the Fraunhofer Institute for Manufacturing Engineering and Automation IPA in Stuttgart that could lead to electric vehicle battery pack costs being slashed notably.

In addition to potential cost cuts, the new prototype could also lead to battery packs with greater capacity (potential range), according to those involved in the research.

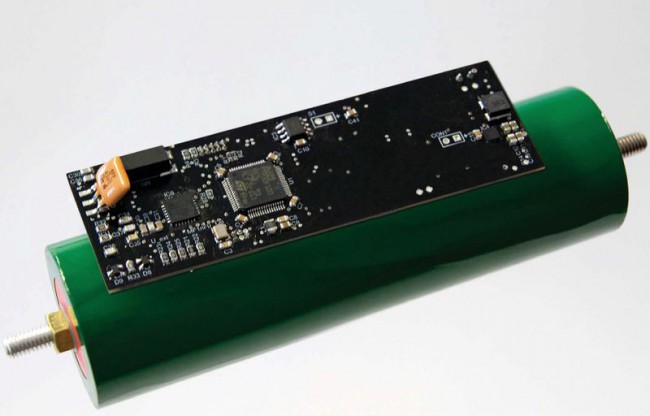

The new prototype battery cells feature built-in micro-controllers that record various physical parameters — temperature, state of charge, etc — and use this information to “communicate†with the other cells (or controllers), thereby allowing for some manufacturing options that didn’t exist previously.

Green Car Congress provides more:

The potential benefits of this come in to play when considering the current state of pack assembly. So far, these have been monolithic blocks in which the individual battery cells as well as the necessary supporting technology have been housed All individual cells should theoretically have the same energy capacity. In practice, though, this is somewhat different: due to production reasons, capacities vary. This is problematic, since the cells are connected in series. The entire battery is therefore only as strong as its weakest cell.

If the charge in this cell is depleted, the remaining energy in the other battery cells does not help — the car has to be recharged. For that reason, manufacturers presort and install cells of a similar capacity into a battery. Since some cells are sorted out as a result of this process, this pushes up the price of the battery packs. Another shortcoming is that when a cell is defective, the vehicle stops functioning.

The new prototype, though, allows for a setup whereby the presence of empty cells doesn’t require the car to be stopped — so long as other cells still possess a charge, that is. The empty cell simply “decouples†from the others (similar to a current by-pass).

The Group Manager at Fraunhofer IPA, Dr Kai Pfeiffer, commented: “Depending on the cell quality, we can therefore increase the range by at least four percent. Over time, this effect is amplified: in the case of an old battery, and if the empty cells are replaced, it is conceivable that a range up to ten percent higher can be achieved.â€

Fraunhofer ISE was a 2014 Zayed Future Energy Prize winner.

Originally published on Sustainnovate.