A team from the Shenzhen Institutes of Advanced Technology of the Chinese Academy of Sciences has developed a novel, environmentally friendly low-cost battery.

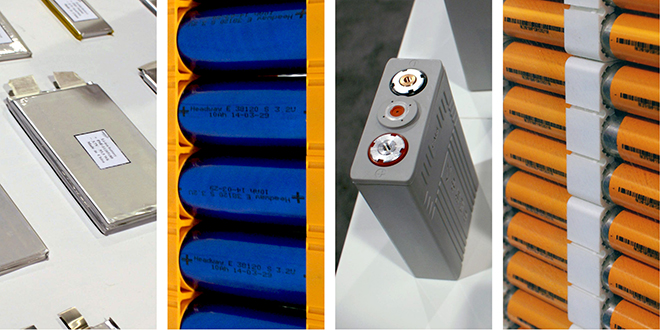

In “A Novel Aluminum-Graphite Dual-Ion Battery,â€Â published in Advanced Energy Materials, Yongbing Tang and colleagues present a new aluminum-graphite dual-ion battery (AGDIB) that they say offers higher energy density than conventional LIBs, as well as reduced weight, volume, and fabrication cost.

The battery shows a reversible capacity of ~100 mAh g-1 and a capacity retention of 88% after 200 charge-discharge cycles. A packaged aluminum-graphite battery is estimated to deliver an energy density of ~150 Wh kg-1 at a power density of ~1200 W kg-1.

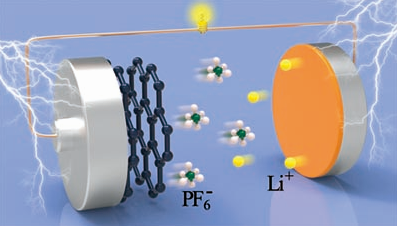

Schematic structure of the AGDIB (Image by Professor TANG Yongbin)

“Compared with conventional LIBs, this battery shows an advantage in production cost (~ 50% lower), specific density (~1.3-2.0 times), and energy density (~1.6-2.8 times),†writes team leader Yongbing Tang.

The volume energy density of the AGDIB can reach ~560 Wh/L, according to the paper, considerably higher than current batteries, for example those used in the Tesla Model S (~350 Wh/L) or BYD E6 (~200 Wh/L).

The AGDIB mechanism follows a dual-ion intercalation/alloying process. During charging, anions in the electrolyte intercalate into the graphite cathode, while the Li+ ions in the electrolyte deposit onto the aluminum counter electrode to form an Al-Li alloy. In the discharge process, anions and Li+ ions diffuse back into the electrolyte.

Since the Al counter electrode in the AGDIB acts as the anode and the current collector at the same time, the dead load and dead volume of the AGDIB are significantly reduced, making a battery with both high specific energy density and high volume energy density.

Unlike most batteries, the AGDIB contains no toxic metals – its electrode materials consist only of aluminum and graphite, while its electrolyte is composed of conventional lithium salt and carbonate solvent.

Source: ChargedEVs